It is a far more complex than how elementary it seems to be, that’s why we consider it a technology and not a commodity, yes, I am talking about the tyres. Tyres not only play an important part in logistics industry but can also give a huge impact on the environment through reduction in fuel consumption and increased tyre mileage hence longer life cycle of a tyre.

There are several very crucial parameters which play a very important role for both fuel mileage and tyre life. For any logistical operations small or large the mentioned are two major benefactors in terms of operational cost involved in running the business.

The major strand on which the highest expense in form of fuel depends through tyres is “Rolling Resistance”. To understand rolling resistance imagine walking on a beach with wet and stiff sand which requires a lot lesser efforts as compared to walking on a dry and loose sand which in turn consumes more energy, similarly tyres with high rolling resistance are equivalent to constantly walking on a dry and loose sand. The rolling resistance is quantified by “Rolling Resistance Coefficient” hence it can be said a tyre with higher rolling resistance coefficient will have higher traction.

As the tyres roll the tread deforms in order to overcome the traction and the energy for this tread deformation comes directly from the fuel tank. The tyre with lower value of rolling resistance coefficient requires lesser energy to roll with improvement in fuel mileage.

The factors on which the rolling resistance coefficient depends are:

- Aerodynamics Resistance which depends on vehicle design and can’t be controlled by any individual and contributes 0-15% of rolling resistance.

- Micro skidding which is related to tyre design and controlling this factor might require considerable investments and time to change, this contributes up to 5% of rolling resistance.

- Shear, Compression and Bending contributes 85-90% of rolling resistance and depends majorly on vehicle maintenance and can be controlled in order to reduce the rolling resistance of tyres and hence the fuel expenses.

Shear, Compression & Bending and hence the rolling resistance of tyres are controlled by:

- Mechanical Health of Suspension, Wheel Assembly, Axles, Brakes

- Inflation Pressure

- Alignment

- Tyre Pattern and Construction

- Unusual and non-uniform tyre wear

- Load on Vehicle

Prompt and preventive control of above mentioned through efficient “Tyre Management” can help any of the fleets to reduce the fuel consumption by decreasing the rolling resistance, as a matter of fact, various studies and research studies suggest that 5% improvement in rolling resistance decreases the fuel consumption by 2% the figures for savings of this comes in few lakhs of rupees on monthly basis.

Tyre Management is a factor which most of the fleet owners are unfortunately unable to execute with utmost efficacy, or even if done desirable results are not achieved by them.

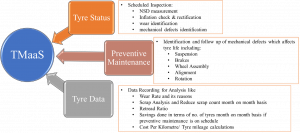

“Fleeca” stands for “Fleet Care”, Fleeca India Pvt. Ltd. is a Jaipur based company with its unique and complete solution-based product designated as “TMaaS- Tyre Management as a Service”. The inclusions of Tyre Management done by Fleeca India Pvt. Ltd. to increase the tyre life of their customers in its own unique way are:

The trusted services of Fleeca India Pvt. Ltd. are being enjoyed by more than 130 customers in 13 states. Our vision is “To become the best tyre management service provider in India for Fleet owners to keep rolling smartly with grip of trust & safety on tough roads” and inch by inch and day by day we are dedicatedly working towards this vision and contributing to the logistics industry and fleet owners to grow and flourish by serving with high quality standards to our clients and ensure that they not only contribute towards saving the environment by reduced fuel consumption and extended tyre mileage but also achieve 2-3% of additional savings in their expenses.

—

Dr. Ankur Sagar

Head- Operation, Learning & Development,

Fleeca India Pvt. Ltd.